Smol Tracker Soldering

This page offers two ways to learn to solder your Smol Tracker: a video tutorial and a step-by-step text guide. Choose the method that works best for you!

Table of Contents

Lyall's Soldering Video Tutorial

If you prefer to watch a demonstration, you can follow along with the video below.

Depact's Soldering Text Tutorial

Tools Needed

Essential Tools

- Side cutter pliers

- Tweezers (used for holding buttons and header pins in place)

- Soldering iron

- Soldering sponge (used for cleaning the soldering iron tip)

- Flux-cored solder wire (recommended for ease of use over separate solder and flux)

- Scissors (used for cutting Kapton tape)

Optional Additional Tools

- Soldering jig (optional, but makes holding the board easier)

- Soldering mat (optional, protects your workspace)

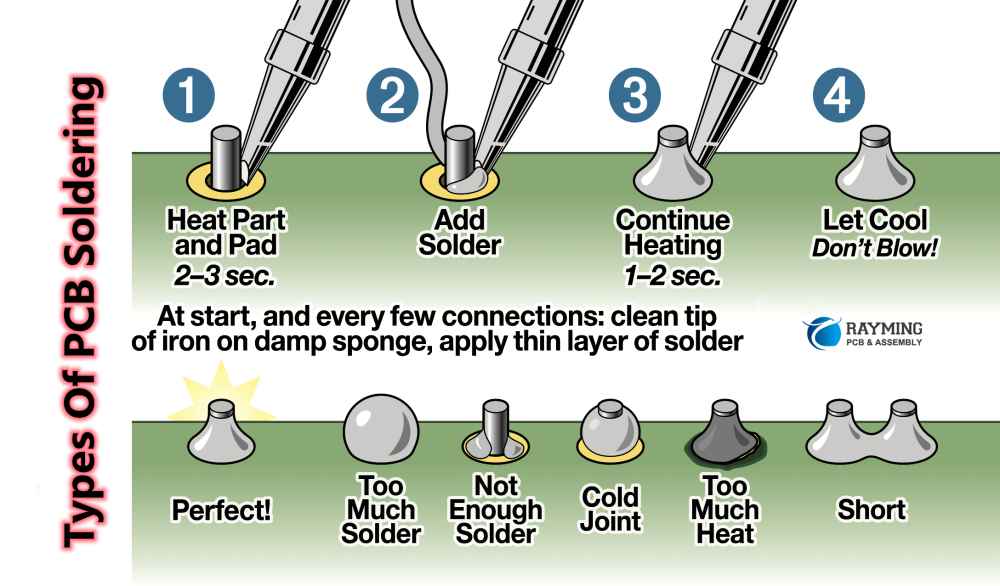

Types of PCB Soldering Defects and Solutions

Visual guide for PCB soldering and identifying soldering defects and proper solder joints.

Soldering Steps

-

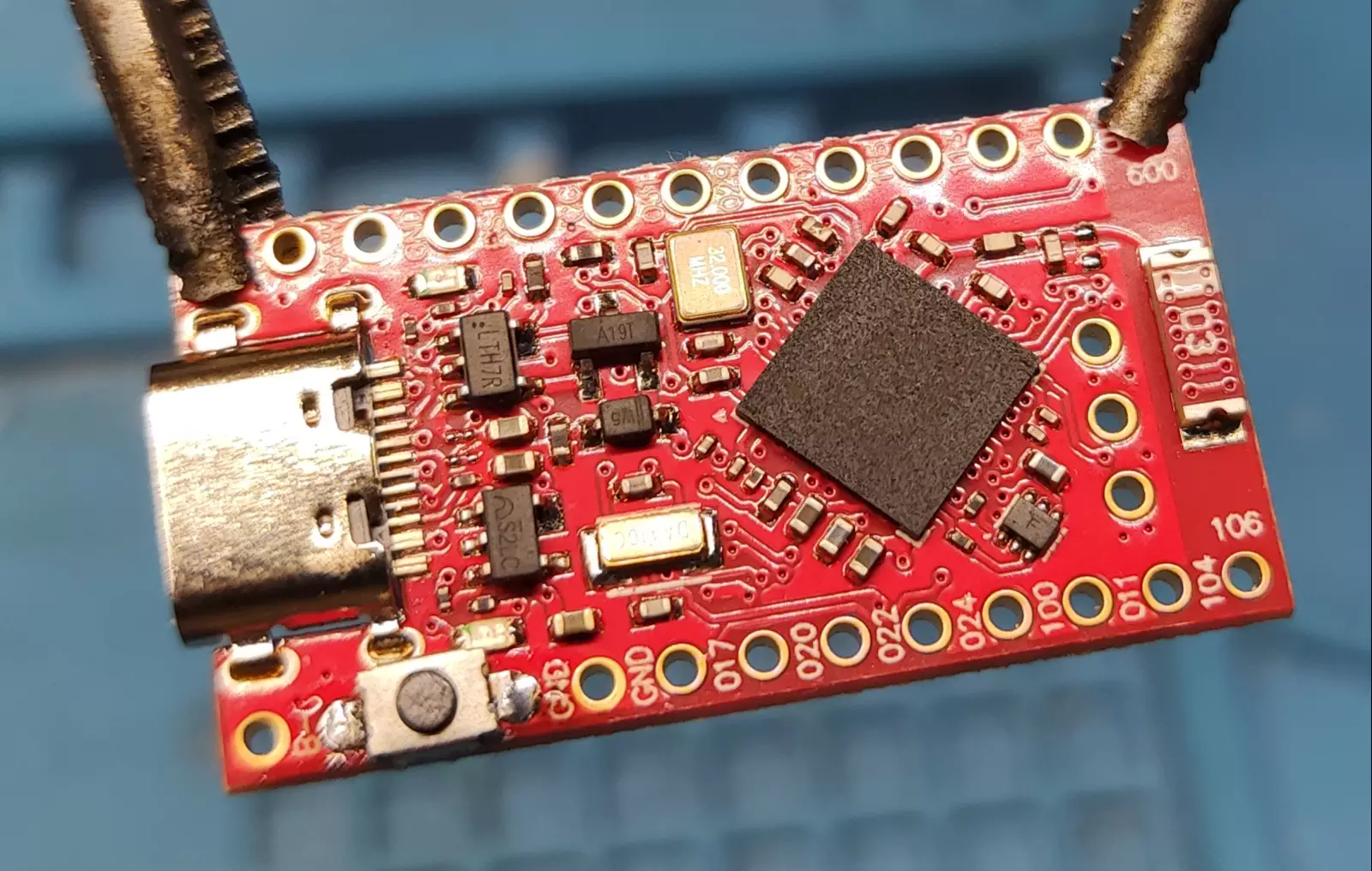

Solder the Button

- Prefill the through-holes under the button contacts with solder.

- Place the button onto the solder-filled holes.

- Heat the area with the soldering iron until the solder connects the button pads securely.

-

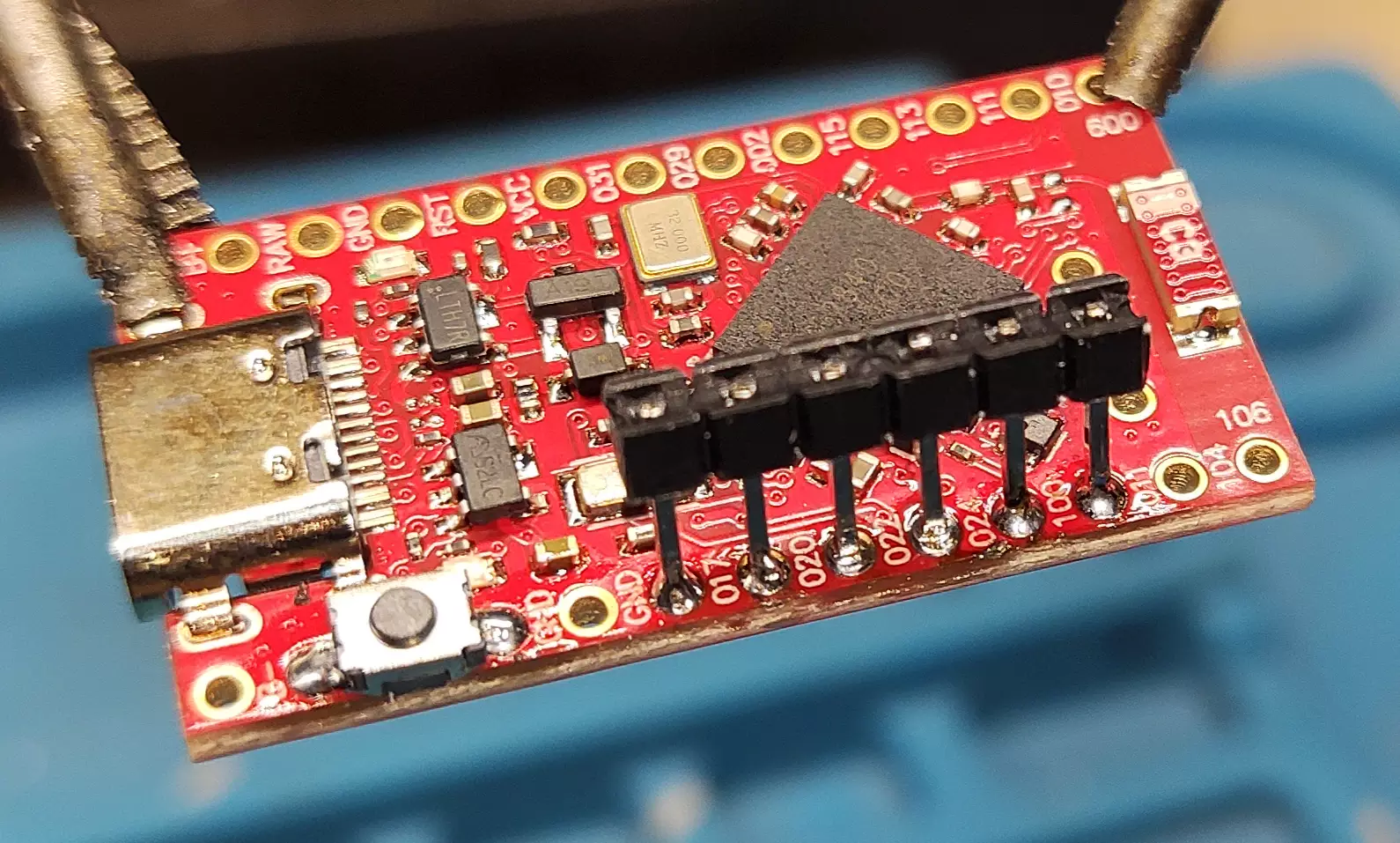

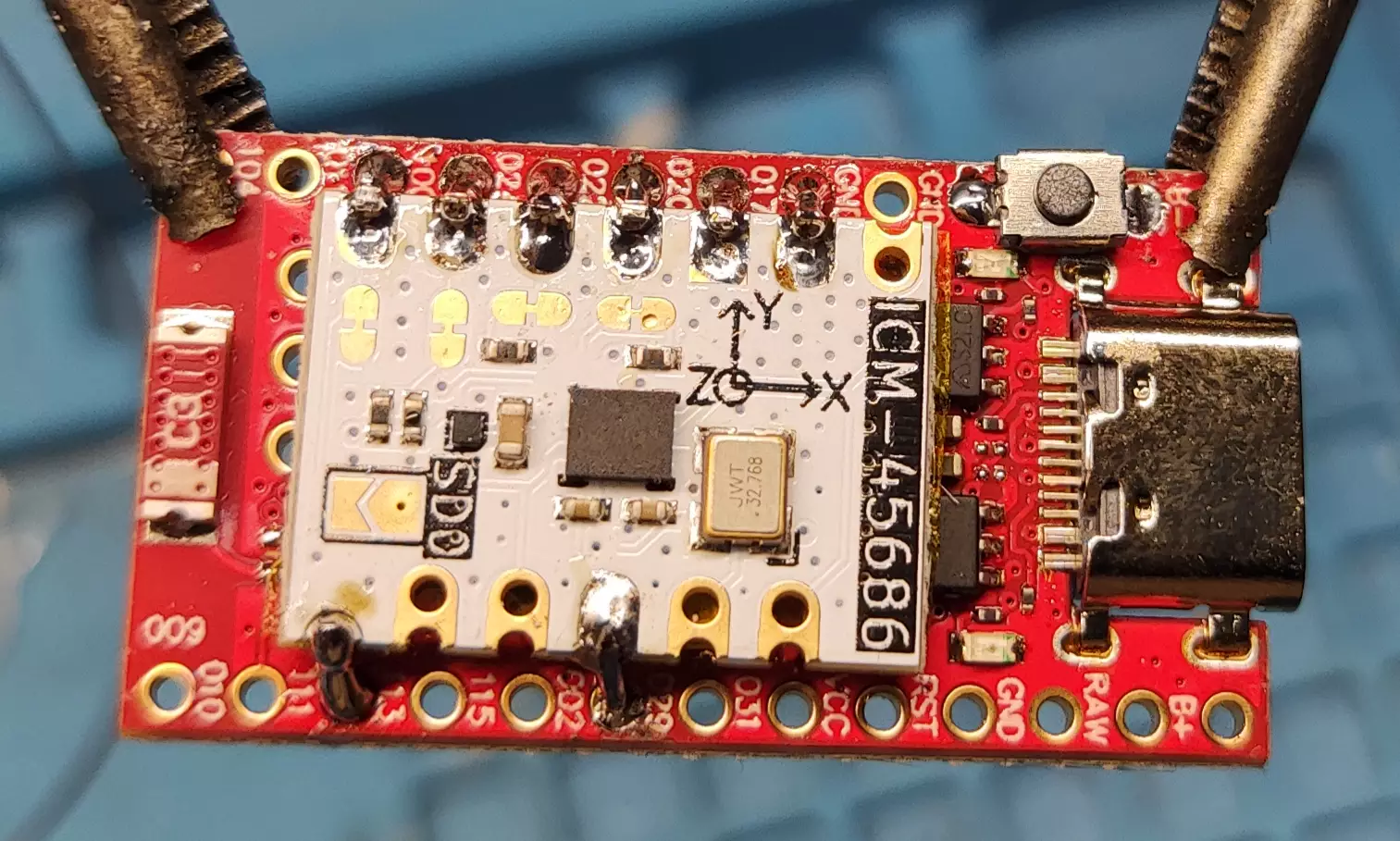

Solder the Breakaway Header

- Break off a segment of 6 pins from the breakaway header strip.

- Insert the header into the through-holes, leaning it slightly toward the center of the board to hold it in place.

- Solder each pin one by one, making sure they remain straight and securely attached.

-

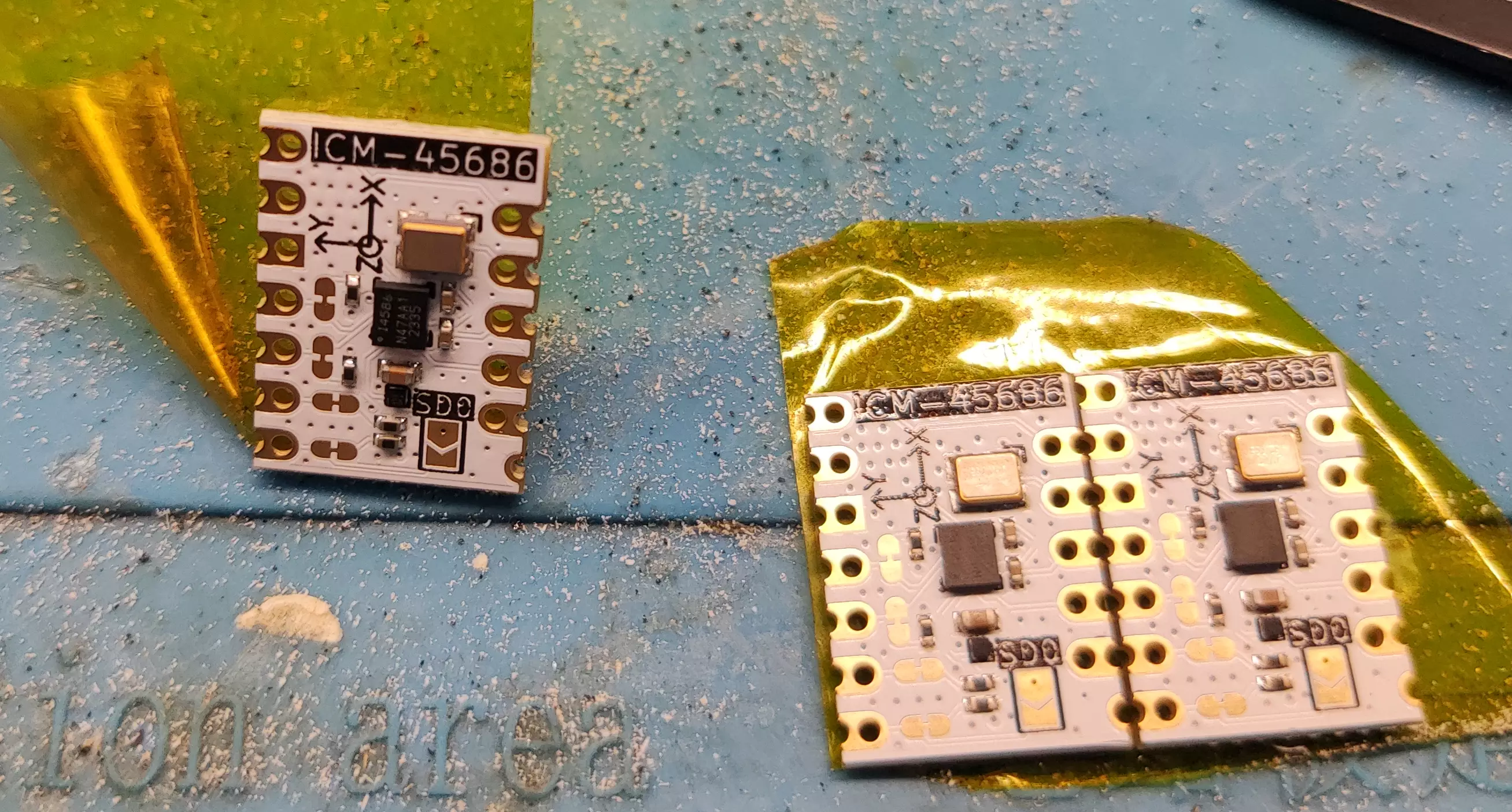

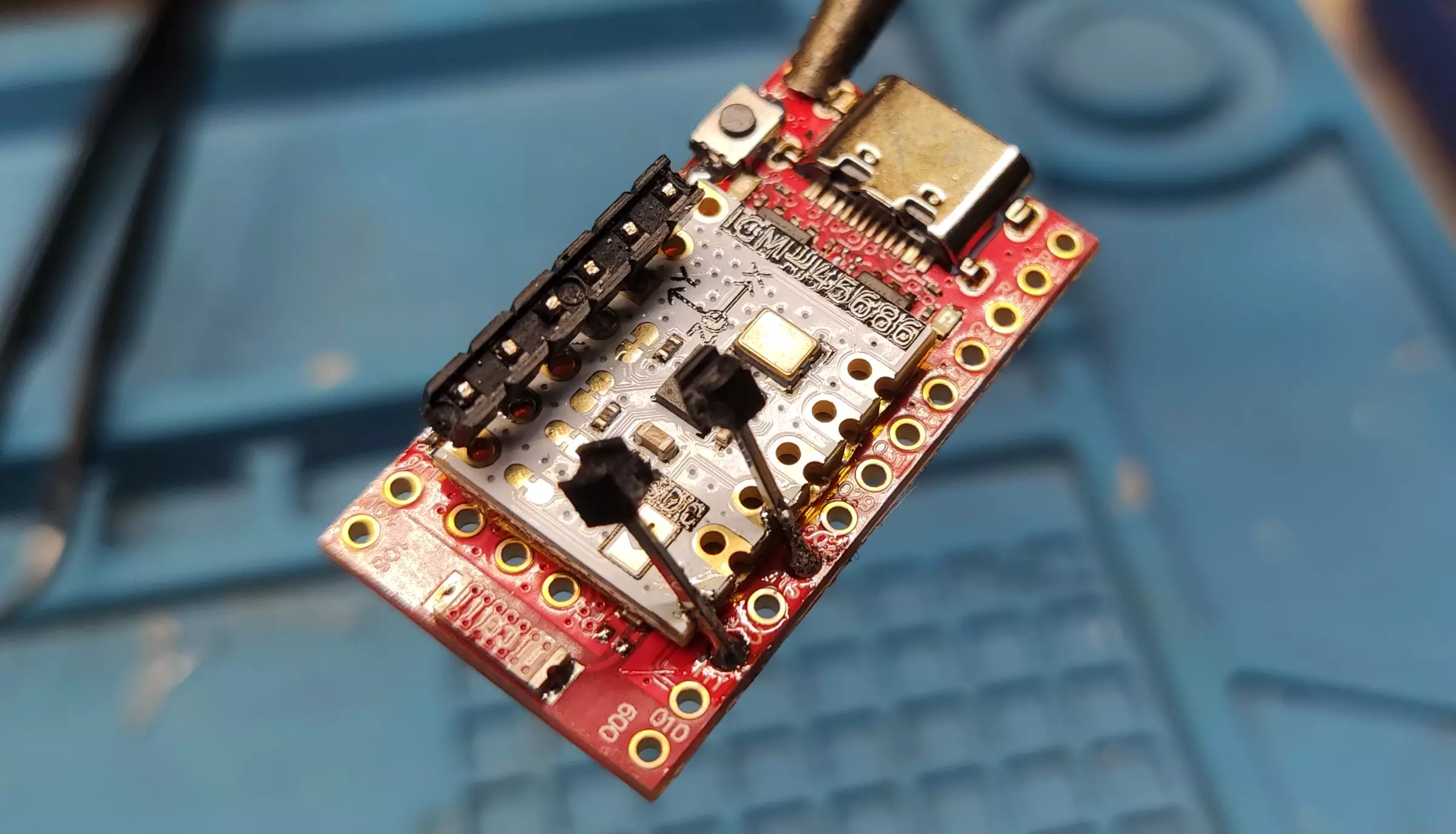

Insulate the IMU

- Cover the back of the IMU module with Kapton tape to prevent shorts.

- Cover the back of the IMU module with Kapton tape to prevent shorts.

-

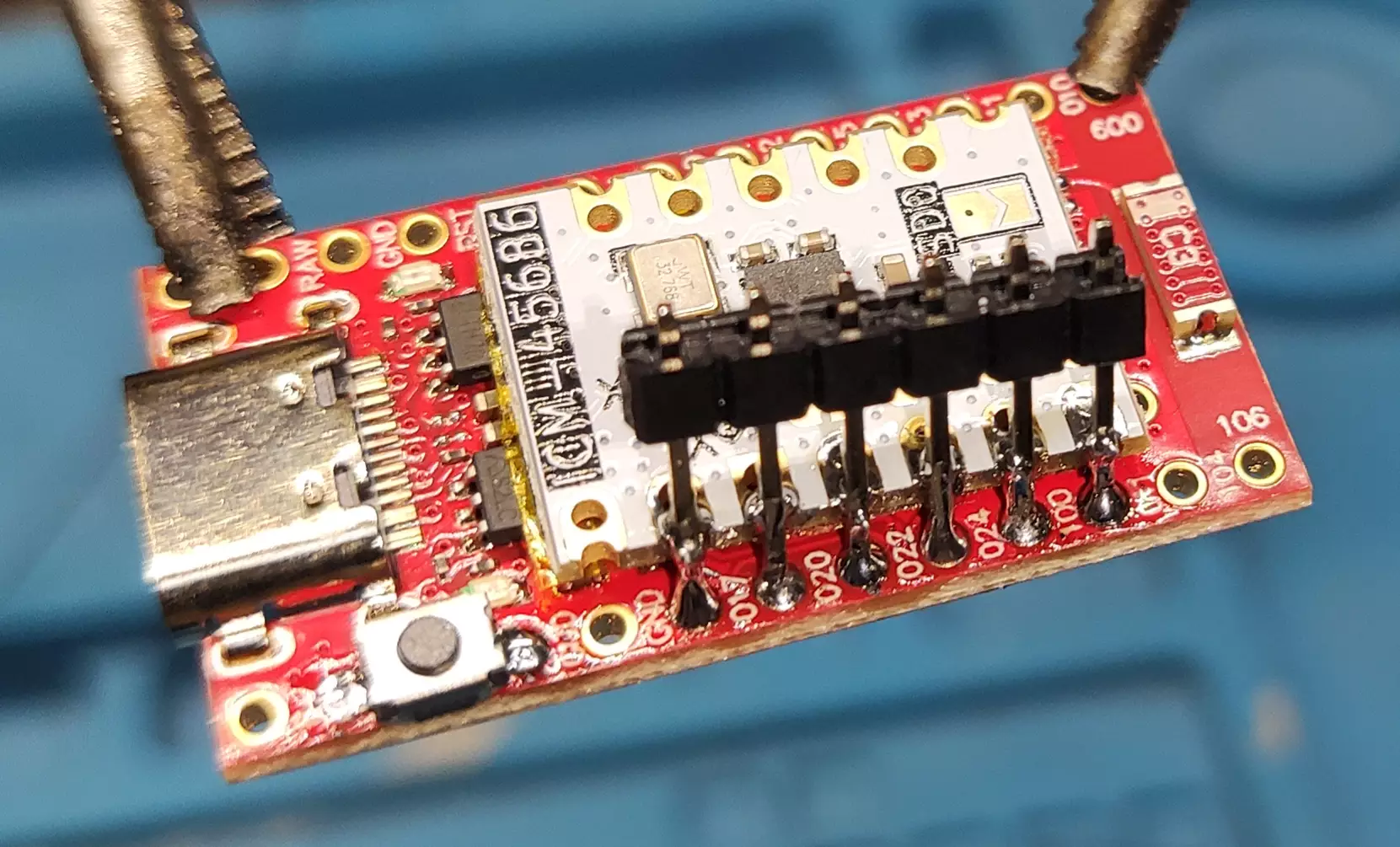

Solder Headers to the IMU

This tutorial shows how to solder the ICM-45686. For other IMUs, see Smol Tracker Schematics.

- Solder a row of breakaway headers to one side of the IMU.

- Solder the headers on the other side at a slight angle so they make solid contact with the IMU pads.

-

Trim and Inspect Header Pins

- Use side cutter pliers to trim excess length from the header pins.

- Inspect the solder joints and add more solder if needed, but avoid overheating, as this can loosen the pins.

-

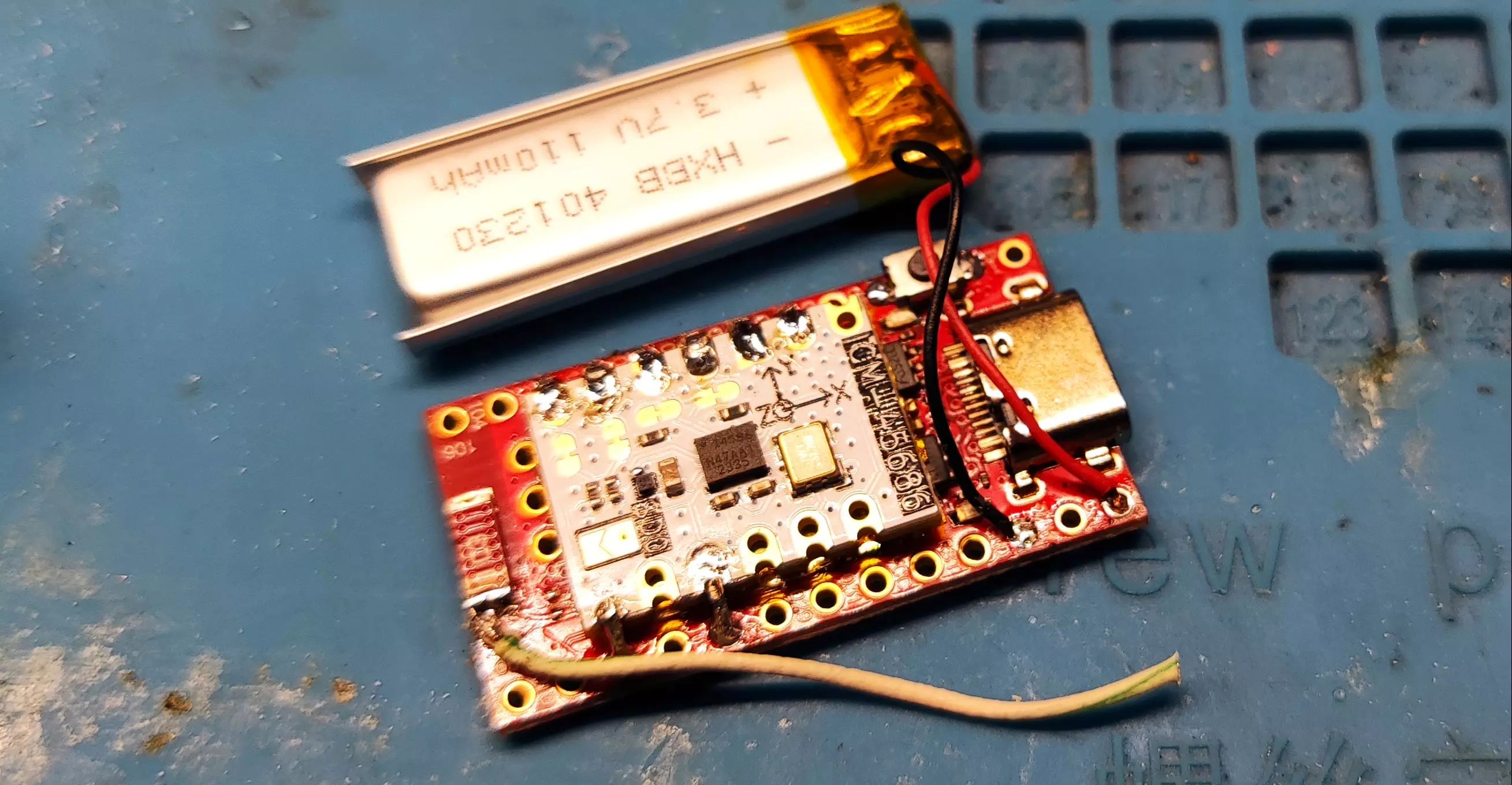

Solder the Antenna Mod and Battery

- Solder the antenna wire and the battery leads to their respective pads.

- For optimal performance, the antenna wire should be cut to 31.2 mm. Any deviation will reduce performance.

Double-check each connection carefully before powering the board.

Use the info command in a serial terminal to check if the IMU is detected. If it is not detected, this usually means there is a soldering issue, or less commonly, a hardware fault.

Additional Materials

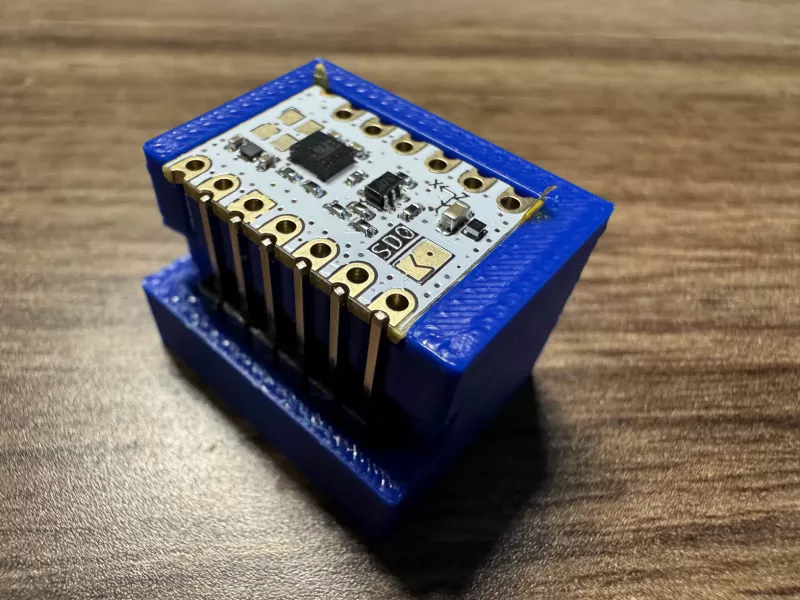

Ibis Soldering Fixture

You can optionally use the Ibis soldering fixture to hold your IMU and headers securely in place while soldering. Note: That this fixture does not work for every IMU, as it is specifically designed for the LSM6DSR/LSM6DSV from Deyta's Moffshop and ICM-45686 from SlimeVR Store.

Created by Shine Bright ✨ and Depact